Professional Automotive Engineers: What Are The Tasks They Do?

When speaking of manufacturing an automobile, you would have to call the attention of professional automotive experts as they are the right individuals with knowledge about it. There are more of their knowledge about automotive because they have extensive training and experience in automobile areas, including:

- Design

- Manufacturing

- Maintenance

- Repair

- Sales

- Regulations

- Industry trends

The professional automotive experts have their roles in the automotive industry discussed at https://chassisman.com/.

Automotive engineers

Automotive engineers are responsible for the following tasks:

- designing

- developing

- improving vehicles and various components

Their tasks encompass various activities throughout the vehicle’s lifecycle, from initial concept to production.

Tasks of automotive engineers

Here are the tasks of automotive engineers:

- Vehicle design. Automotive engineers work on designing new vehicles or modifications to existing ones. They focus on aspects such as:

- exterior and interior aesthetics

- aerodynamics

- ergonomics

- overall vehicle architecture

- Engine and powertrain development. They design and optimize engines and powertrains for improved performance, fuel efficiency, and emissions. It includes working on:

- combustion engines

- electric motors

- hybrid systems

- Chassis and suspension design. Engineers develop chassis and suspension systems to ensure vehicles have stable and comfortable handling characteristics. They consider factors, such as:

- ride quality

- stability

- responsiveness

- Safety systems. Automotive engineers design safety features to protect residents and pedestrians in case of an accident. These features may include:

- airbags

- collision avoidance systems

- crumple zones

- structural reinforcements

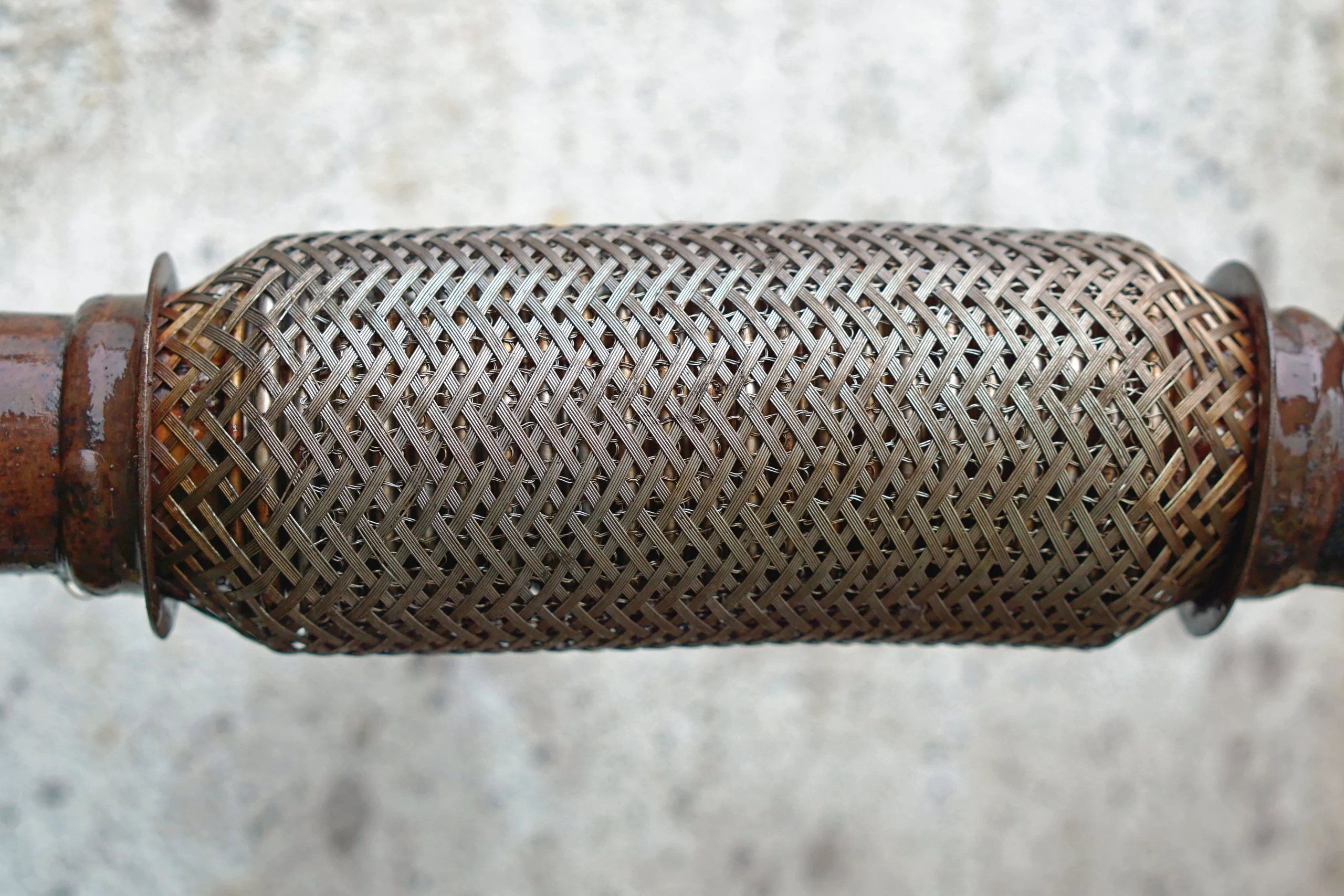

- Emissions control. They work on technologies to reduce harmful emissions from vehicles to ensure compliance with environmental regulations. It may involve the following:

- developing catalytic converters

- exhaust systems

- emissions control strategies

- Materials selection. Engineers choose materials for various vehicle components, considering factors, like:

- strength

- weight

- durability

- Cost

They may experiment with new materials to improve performance and reduce environmental impact.

- Testing and validation. Automotive engineers conduct extensive testing and validation procedures to ensure that vehicles meet safety, performance, and durability standards, including:

- laboratory testing

- computer simulations

- real-world testing on tracks and roads

- Vehicle dynamics. They analyze and fine-tune vehicle dynamics, including:

- handling

- steering

- braking

It guarantees a secure and enjoyable driving experience.

- Fuel efficiency. Engineers focus on improving fuel efficiency through various means, such as:

- optimizing engine efficiency

- reducing weight

- enhancing aerodynamics

- Electronics and control systems. They design electronic systems and control algorithms for functions, such like:

- engine management

- infotainment

- advanced driver assistance systems (ADAS)

- autonomous driving features

- Cost analysis. Automotive engineers assess the cost implications of design decisions and manufacturing processes to ensure that vehicles remain competitive.

Automotive engineers or experts work in multidisciplinary teams, collaborating with professionals in various fields to bring vehicles from concept to production.